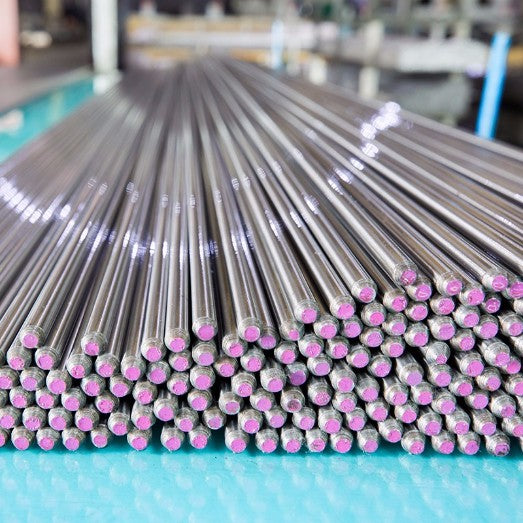

20cr round steel

20Cr is a steel grade with low hardenability, carburizing steel. It is primarily used to manufacture carburized parts with high core strength requirements, surface wear, cross-sections under 30mm, or complex shapes subject to low loads.

Company phone: 0769-83775310 83775312

Product Introduction

20Cr is a steel grade with low hardenability, case-hardening properties. It is primarily used for carburizing parts with high core strength requirements, surface wear, cross-sections under 30 mm, or complex shapes but low loads. This steel is primarily used for carburizing parts (oil-quenched) with high core strength requirements, surface wear, cross-sections under 30 mm, or complex shapes but low loads. Examples include machine tool gearbox gears, gear shafts, cams, worms, piston pins, and dog clutches. For parts requiring minimal heat treatment deformation and high wear resistance, such as gears, shafts, and spline shafts with a module less than 3, high-frequency surface hardening should be performed after carburizing. This steel can also be used in the quenched and tempered state for parts subject to high operating speeds and moderate impact loads. It can also be used as a low-carbon martensitic hardening steel, further increasing the steel's yield strength and tensile strength by approximately 1.5-1.7 times.